command access approached us to design a smart lock FROM ground up

Command Access Technologies, a California based lock manufacturer, approached OCDLab to design a smart lock from the ground up. The Smart Module would be used with Command Access’s existing line of motorized locks as well as a new product line.

THE

CHALLENGE

When working with an existing product line, there are several challenges involved. For example, the module should plug into the current products seamlessly. The power circuit should be compatible with the existing voltage conditions. Given the limited space, a smaller footprint would be critical. The list just goes on and on…

| SMALL FOOTPRINT Given the limited space, it was imperative that the module didn’t take a lot of space. After adding battery housing, there was very limited space for the chipset.. |

| BATTERY LIFE For battery-operated locks, power consumption plays a huge role. The system should work on 2 AA batteries for at least 6 months, if not more. | |

| WIFI ENABLED For remote access management, an optional wifi module was required but due to higher power consumption, we couldn’t install it on the primary chipset. | |

| COST EFFECTIVE The lock market is highly competitive, and thus the customer had a strict upper cap for MRP. |

WHAT WE DID.

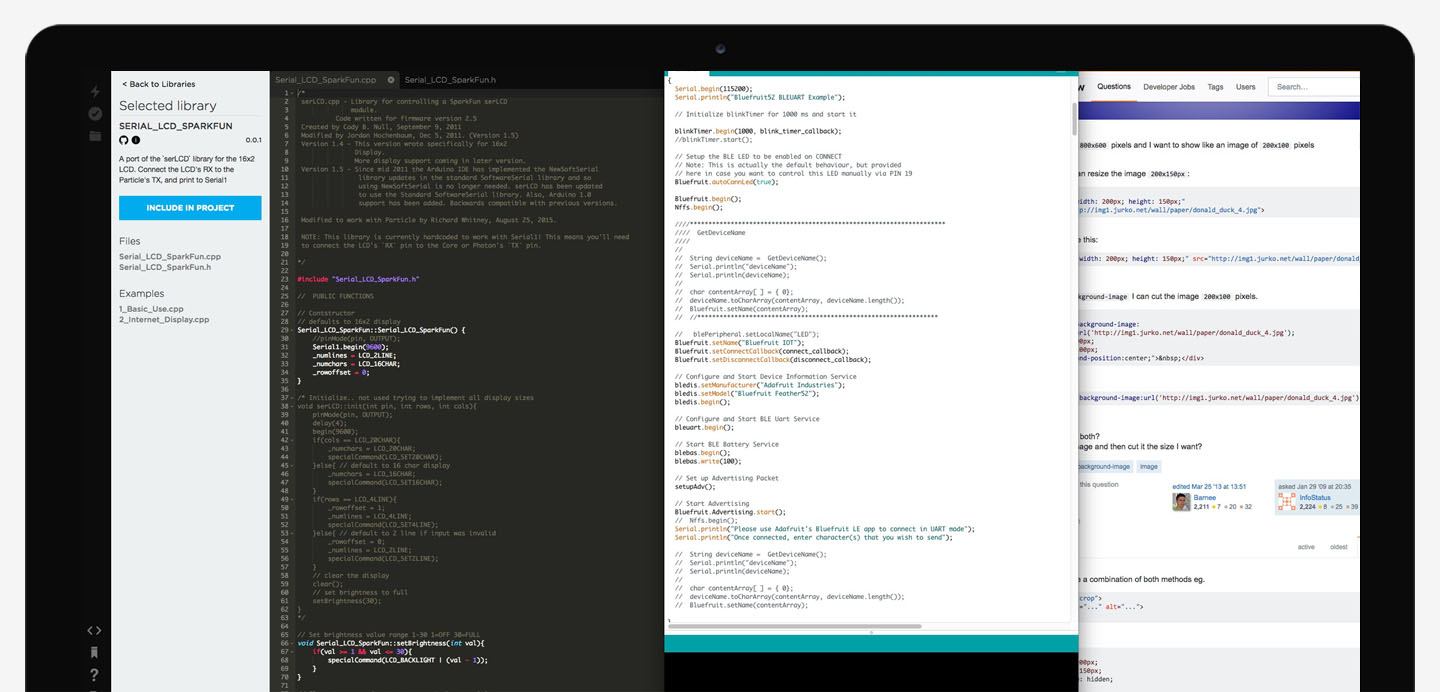

The OCDLab team offered a turnkey solution from conceptualizing to prototyping to firmware development and designing. We started with developing a basic understanding of product line, hardware limitations, and the lock market in general. This helped us in aligning our goals and thought processes with the customer. We chose Arduino as our test bed for its simplicity and ease of programming and eventually landed on Particle for the final version.

HARDWARE PROTOTYPING

Chipset prototyping using Arduino and Particle.io

FIRMWARE DEVELOPMENT

Once we agreed on the chipset, next step was to write a light weight firmware.

BACKEND DESIGN

For remote access management, we needed a robust backend to control the locks over wifi and cellular.

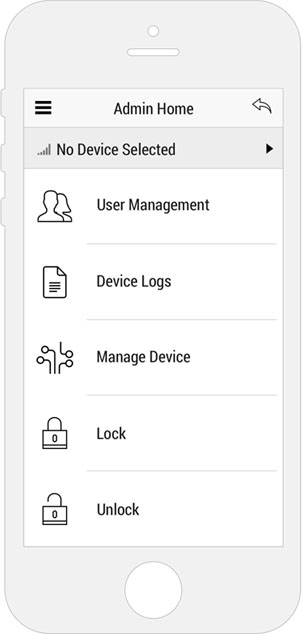

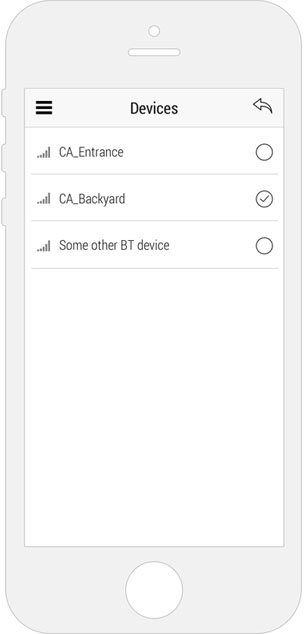

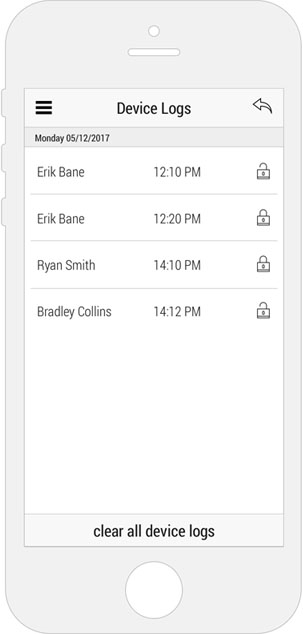

MOBILE APP

The final piece to bring it all to life. A mobile app for end users.

THE PROTOTYPING PHASE

Choosing the right chipset is very important. With most of the modern day IoT products, the physical size of the device is relatively small, and you want to pack as much processing power as possible without losing the valuable real estate and stability. We started with Arduino as our testbed but soon realized that it would not be an ideal fit for production scenarios due to limited storage and wi-fi compatibility. We then started exploring other options and finally decided to go with Particle which has a small footprint and ready for production.

FIRMWARE DEVELOPMENT

Writing Firmware is always the fun part. This reminds us of what programming is all about. Limited processing power and storage means the code needs to be highly optimized and lightweight. A small mistake can render the whole experience useless.

USER EXPERIENCE DESIGN

The user experience can literally make or break a product, especially in the consumer space. The OCDLab team toyed with several ideas before coming up the ideal user flow. The customer was extremely happy with the minimalistic approach and how it doesn’t make the user think.

- Identity Management

- Remote Lock/Unlock

- Remote Access Management

- Wifi and Bluetooth Compatible

- Temporary Access

- Log Management

- Day/Night Mode

WHY OCDLAB

Customer Quote

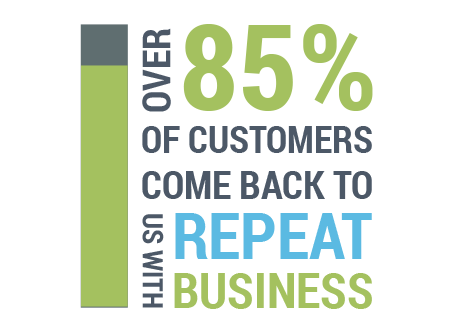

“OCDLAB is awesome. I’ve used their services for more than 10 years. They’re the first company I go to for any work, and I’ve recommended them to many people. No one has ever come back to me with a negative comment.”

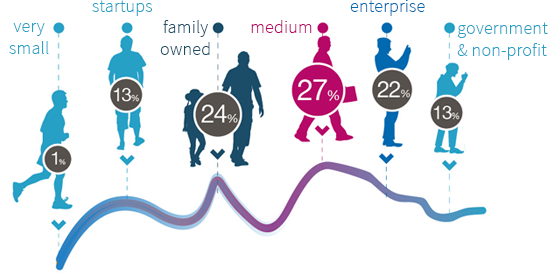

WE APPEAL TO CUSTOMERS ACROSS ALL BUSINESS SEGMENTS.

Customer Quote

“OCDLAB will challenge me when they feel I’m missing something. They’ll make sure I’m thinking it through properly, and guide me if I’m going in a wrong direction. It’s helpful to have this, as opposed to doing everything I say.”